Custom Solutions

X-ES sets itself apart using a design methodology with an eye towards fast and efficient customization, enabling rapid time-to-market solutions. Our engineers can provide custom designs ranging from modifications of existing products (referred to as derivative designs or “modified COTS” products) to fully customized designs.

Derivative Designs

Assembly-Line Methodology

X-ES offers a robust and diverse standard product line, but a close look at both our Commercial-Off-The-Shelf (COTS) products and derivative designs will reveal similarities between products and even across form factors. That’s because whenever possible, our engineers begin with an established and thoroughly tested design, then tailor it to customer- and platform-specific needs instead of starting from scratch each time.

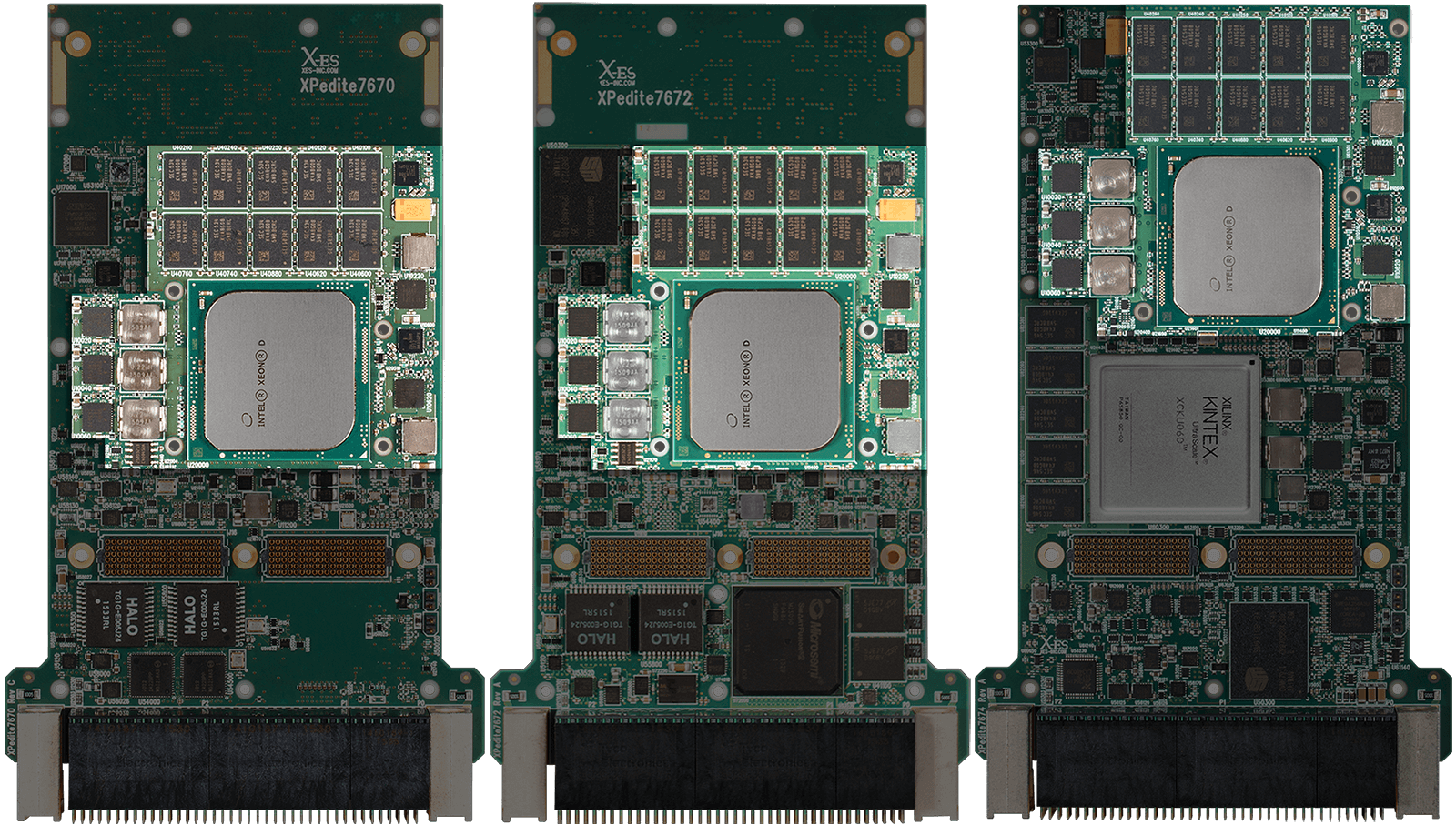

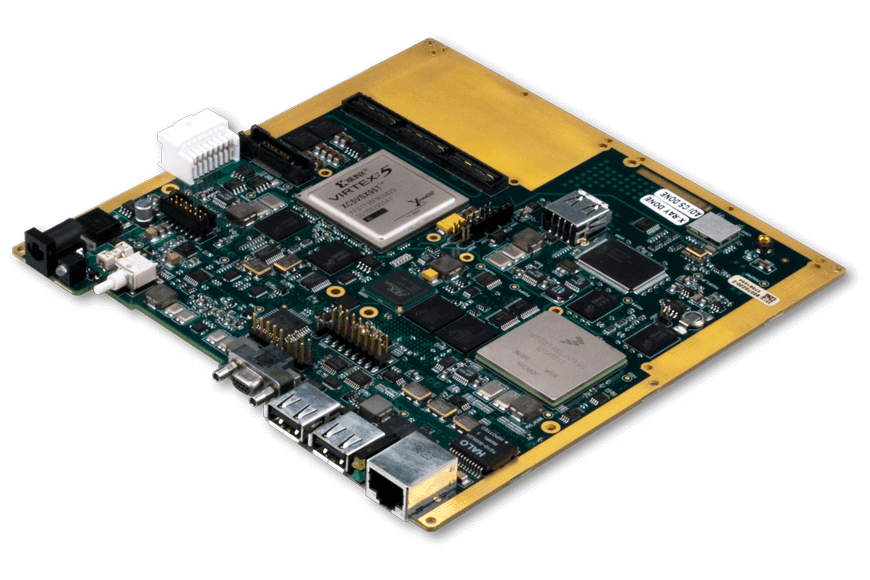

By re-using trusted elements (such as the highlighted processor system) and then adding or removing functionality as needed, we can deliver derivative designs faster than the competition. The X-ES design methodology allows us to carry functionality and features from one industry-standard form factor to another:

- 3U VPX

- 6U VPX

- 3U cPCI

- 6U cPCI

- 6U VME

- XMC/PMC

- COM Express

- ATCA

- E-ATX

We also support fully custom form factors specifically tailored to meet physical size, shape, space, and weight restrictions.

With low management overhead and a strong commitment to responsiveness, X-ES can follow up on requests for derivative products in days or even hours, depending on the scope of the project. Our derivative design methodology cuts down on the guesswork that typically accompanies defining timelines. We can more reliably predict the time it takes to design, build, and test products, allowing us to hit even our customers’ most aggressive schedules while keeping costs under control.

By enforcing consistency at every opportunity, we also reduce risks at every stage of the process:

Engineering

Derivative design allows X-ES and our customers to run a single codeset across multiple applications and deployments for more reliability and interoperability. Reuse of proven functionality also eliminates the risk of introducing new hardware design flaws or software bugs.

Manufacturing

X-ES’ extensive expertise in designing ruggedized, deployable solutions ensures and unparalleled level of dependable performance in the field, reducing the likelihood of servicing requirements over the life of the product and reliance on field technicians.

Support

X-ES understands how critical uptime is to our customers, and the frustration that can stem from development delays. Our dedicated team of support engineers provide rapid responses to technical support questions at every stage of your product development.

Modifications to Your Specifications

Buying COTS products can sometimes mean paying for functionality you don’t need to get the functionality you do. Derivative designs put customers in the driver’s seat to specify only what’s needed to keep projects on budget and optimize for SWaP at the same time.

Here are some typical modifications we’ve made to fine-tune our products to fit a customer’s precise needs for an application or platform:

- Remove unneeded functionality to reduce power consumption

- Add, remove, or move I/O ports

- Add or remove Gigabit Ethernet controllers

- Add or remove FPGA subsystems

- Convert on-card power supplies to different voltage

- Add software support to accommodate hardware customizations

- Combine separate products into a single design

Custom Designs

Just the Right Fit, On‑Budget and On‑Schedule

X-ES has made its reputation working hand-in-hand with customers to fine-tune and execute solutions. X-ES design engineers can work with customer teams to turn a set of specifications into a full design spec and keep in touch during the design process, meeting regularly to discuss project status and scheduling. If necessary, we can work with customers’ mechanical design teams to help develop, model, simulate, and verify the chassis that the product would be housed in.

We’ve even had customers come to us after having issues with a competitor they originally selected. In these situations, we’re often able to respond rapidly to requests and make up for lost time. Our embedded products offer a standard and reliable set of tools to work with, allowing you to focus on the end result of your implementation and not the components.

Why Use a Custom Form Factor?

COTS products and even standard form factor derivative designs can be physically difficult to fit into the actual spaces allotted by certain projects. This can lead to improvised accommodations that might not hold up to the environmental conditions that await these systems—the embedded hardware equivalent of wrapping eggs in bubble-pack—and a lack of clear responsibility for the final product and its performance.

Many of our customers rely on products being able to stand up in extreme conditions in mission-critical situations that can make the difference between safety or disaster. In these scenarios, it pays to choose products that were custom designed and built to purpose for a perfect fit.

Case Study: Multiple-Platform Solutions

Architecting embedded computing solutions across multiple platforms is never a simple task. Each separate platform comes with its own considerations that have to be assessed individually, which can be daunting enough without having to make each piece of the puzzle fit together as a whole. Each potential issue is multiplied by the number of different platforms, with the diversity within a project making common solutions difficult to find.

When faced with the inherent complexity of multiple platforms, it’s tempting to turn to solutions that look easy on the surface.

The One-Size-Fits-All Approach

Find a single vendor with a single product that meets every platform’s needs

A standard solution, flexibly and creatively deployed, might seem ideal. But making fewer decisions upfront can mean more time and frustration spent on the back end figuring out how to accommodate the differences across platforms.

The Pick-and-Choose Approach

Find different vendors, each one providing a specific solution for a specific platform

Different vendors mean different expectations, different pricing, and different scheduling. Even assuming all the vendors are offering equally competent support, this approach can’t help but increase the amount of management and communication needed to solve problems, drawing focus away from the end result of the project itself.

The Elegant Approach

Let X-ES tailor custom and derivative solutions across platforms

Instead of trying to fit square pegs into round holes, why not build round pegs in the first place? What this means is taking the same considerations you would make after purchase to fit the solutions you’ve bought into your various platforms, but working those decisions into the design of the solutions themselves. It means working with a single vendor to supply embedded computing products designed to accommodate each discrete platform.

Customizing hardware upfront saves on downstream adjustments and accommodations because our products are designed to customer specifications from the very start. And unlike one-size-fits-all solutions, each product can be tailored for each platform to maximize performance and eliminate feature bloat. X-ES custom and derivative designs supply products that accommodate the platform’s needs instead of forcing platforms to accommodate the product’s needs.