Temperature Testing

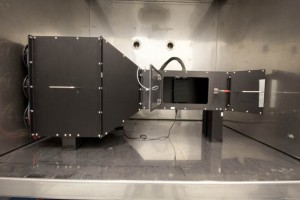

Thermal Chambers

Every deployable unit delivered is subjected to environmental stress screening (ESS) at levels based on customer needs to identify and isolate defects that might lead to product failure. If a product has components that are not rated for the product’s operating temperature range, we also perform temperature uprate screening (TUS).

X-ES has an on-site environmental testing lab outfitted with the following models of thermal chambers:

- Envirotronics EV92-LN2

- Thermotron SE-300

- Thermotron SE-600

- Thermotron SE-1000

- Thermotron FA-35

With these chambers, X-ES engineers perform a variety of tests to evaluate performance under different conditions, including tests at constant temperatures, cycling temperatures, and shock temperatures. The chambers are located in an ESD-protected area and dedicated to manufacturing testing.

Engineers monitor temperatures at multiple points of interest via calibrated data acquisition systems. They can independently control the temperature of the thermal interface surface, using liquid nitrogen (LN2)–cooled fixtures for conduction-cooled systems. All temperature tests can be combined with humidity and/or altitude tests.

Low Temperature Testing

X-ES is capable of performing low temperature tests to replicate operational and non-operational environmental conditions.

- Operational: Perform low temperature operation per the ruggedization level of the product.

- Non-Operational: Perform non-operational storage temperature testing.

High Temperature Testing

X-ES is capable of performing high temperature testing to replicate operational and non-operational environmental conditions.

- Operational: Perform stress tests at the maximum operating temperature to verify performance and functionality.

- Non-operational: Perform non-operational storage temperature testing.

Air-Cooled Testing

Air-cooled testing is performed in one of two wind tunnels designed for either COTS SBCs or chassis systems. The wind tunnels are capable of proving air speeds up to 1,000 LFM (Linear Feet per Minute) and recording air temperature across the product being tested.

Temperature Shock

Temperature shock applies stress to products due to the difference in thermal expansion coefficients of various materials in a system. Operational and non-operational testing is possible.

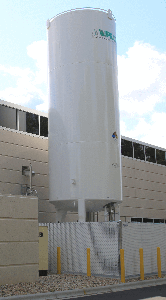

LN2

X-ES uses liquid nitrogen (LN2) for low-temperature testing environments. Liquid nitrogen cooling creates reduced-condensation test environments free of foreign object damage (FOD) while providing consistent, reliable, and expedient temperature testing.

Temperature Tests

X-ES engineers have experience performing the following tests for system- and board-level qualification efforts:

- MIL-STD-810 Non-operating high temperature

- DO-160 Non-operating high temperature

- MIL-STD-810 Non-operating low temperature

- DO-160 Non-operating low temperature

- MIL-STD-810 Operating low temperature

- DO-160 Operating low temperature

- MIL-STD-810 Operating high temperature

- DO-160 Operating high temperature

- MIL-STD-810 Temperature shock

- DO-160 Temperature variation